International Pharmaceutical Leader

« Inventory optimisation »

-

Initial Status

- Performance stock metrics : Shared objectives are missing and/or not cascaded along the process

- Inventory analysis:

- Stock coverage is 14 months for one major product and above 5 months for other products

- No inventory targets (min/max) are calculated

- Stock is mainly composed of WIP located at internal plants or CMO and significant part of the inventory is old and ultra slow movers items (i.e. 42% of stock value for one major product is at one production site and is > 1 year old)

- Cost of obsolescence linked with supply chain issues is 20 M€

- Lead time :

- Lead time is mainly made of waiting time (including shipment time to CMO and release time)

- Visibility on lead times along the supply chain is low

- Planning process and tools:

- High product flow complexity has to be managed in planning (process / tools)

- Risk: Planning process rules are managed individually and implemented in Excel including MRP calculation (i.e. 53 Excel sheets for S&OP of one major product)

- Lack of master data fulfilment in SAP

- Stock culture, responsibilities and ownership:

- Focus are on financial aspects of inventory rather than on operational performance ones

- Few process control and planning standards

-

Project objectives

- Reduce the total inventory level by 10 M€ in 2015 and by 10M€ again in 2016

- Define objectives and computed targeted stock levels

- Realize S&OP field coaching and increase master planners competencies

- Optimize inventory strategy

- Define performance stock metrics and ownership

- Design supply chain "TO BE” processes

- Mitigate risk at master planning level

- Integrate supply chain complexity in requirements stage of the new ERP project (i.e. postponement strategy / “alternative BOM”)

-

Actions taken

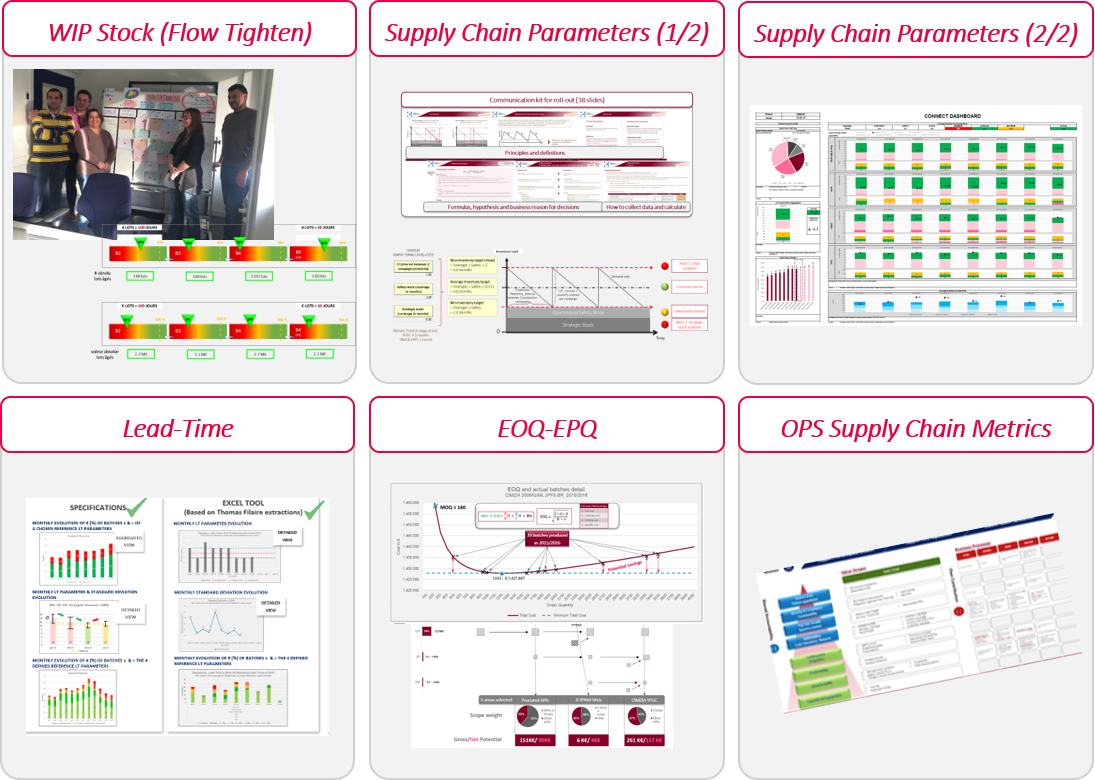

1. WIP Stock:

- Decrease lead-time distribution

- Reduce in-progress inventory

- Identify and analyze under performance causes

- Implement flow tighten

2. Supply Chain Parameters:

- Define inventory parameters computation methodology

- Define reliable and understood parameters

- Share and implement common parameters

- Monitor inventory levels (in terms of coverage) with regards to inventory minimum and maximum levels

- Realise training and field coaching

3. Lead Time:

- Analyse lead times and quantify improvement potential (per plant / product)

- Define target lead times per production stage

- Identify constraints and structure an EOQ / EPQ approach

4. EOQ / EPQ / Production Frequency:

- Compute economical production frequencies and quantities with a pragmatic approach

- Build the EOQ / EPQ model

5. Operational Supply Chain Metrics:

- Map the “AS IS” supply chain monitored KPI

- Underline gaps and propose a shared Balanced Scorecard (BSC)

- Cascade KPIs and objectives from BSC to operational teams

- Develop prototypes for KPIs

Gains obtenu

Quantitative gains

- Savings of 29 M€ linked with inventory performance optimization delivered by the client, supported by Resultance

- Inventory reduction of 16M€ in 2015

- Inventory reduction of 13M€ in 2016

Qualitative gains

- Strong involvement of cross-departments teams

- Innovative and pragmatic approach: flow tighten at internal production sites

- Consensus on supply chain parameters and targets

- Continuous monitoring of inventory coverages

- Mindset evolution regarding inventory performance

- Creation of an Economic Order Quantity (EOQ) model

- Increased visibility and accuracy for management

- Synergies with the new ERP project