Paint manufacturer SME

« Logistics optimization »

-

Initial Status

- Clients: broad customer base but just a few of them contribute largely to the turnover. However, the same level of service is provided to all.

- Products: large number of references in stock, a lot of which have a low turnover. Systematic differentiation of products causes storage problems.

- Storage: several storage sites with each having its own logic and organization.

- Logistic flows: many people involved in the flow of orders and many different logistic flows, reducing the efficiency of the system.

- Balance between work load and capacity: the workload fluctuates during the day, the week and the year. The resources are not always well-adapted (flexibility).

- Transportation: there are many orders of small size and the delivery costs are not billed.

-

Project objectives

- Increasing the staff's efficiency by 10% (flow of orders).

- Reducing storage and transportation costs.

- Improving customer satisfaction.

- Better defining and clarifying the service offer.

- Rationalizing the range of products.

- Finding the most appropriate steering tools for the company (KPI).

The financial impact is estimated at 250k€ per year.

-

Actions taken

Implementation of 5 workstreams to achieve the project objectives

A - « Services and goods offer » workstream: defining and settling the services offer, analyzing and rationalizing the range of products, identifying the costly clients' behaviors and disposing of them.

B - « Order entry and preparation » workstream: organizing the order entry and optimizing the computerization of the purchase order, as well as the workload/work capacity balance .

C - « Goods storage and delayed differentiation » workstream: analyzing the packaging and the feasibility of a delayed differentiation (« slow movers »).

D - « Delivery and transportation » workstream: conducting a comparative study on insourcing or outsourcing transportation, improving the rounds, defining the organization rules of the rounds.

E - « Dashboard and steering tools » workstream: defining and setting up an operational dashboard for every site, as well as a control framework, defining the KPIs.

Gains obtenus

Quantitative gains

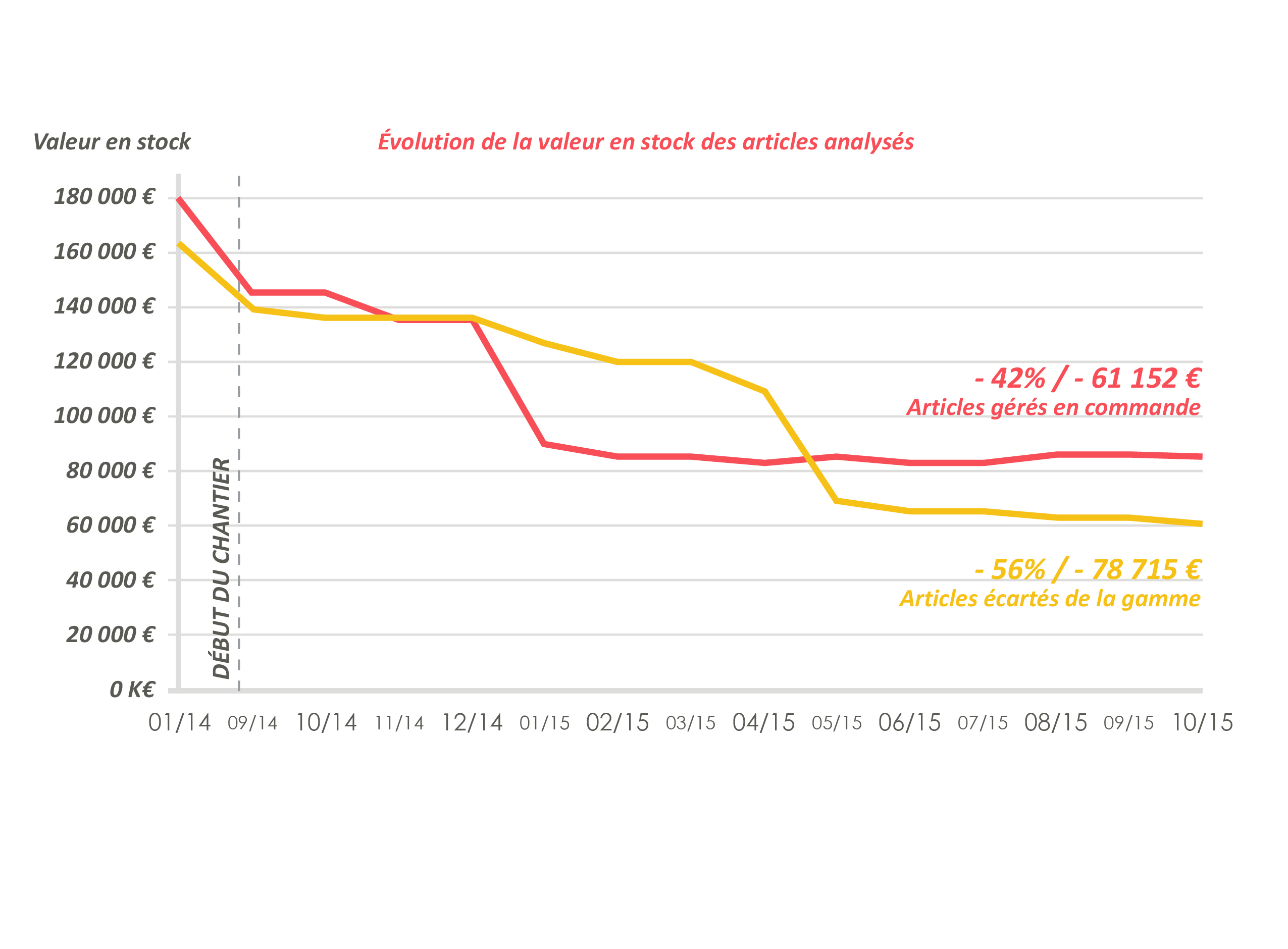

- Reduction of 140 k€ in the value of the stock.

Qualitative gains

- Rationalizing the "negotiation" range: dashboard.

- Order entry and preparation: defining and settlliing a new modus operandi + training (2 sites).

- Efficiency of order preparation: implementing the "optimal preparation process" method (+128%).

- Delayed differentiation in production line: - 1/3 of the articles, defining the storage rules.

- Transportation logistics: improvement of the system of the rounds + PDCA.

- Defining and settling the service offer of logistics.

- Process of monitoring the non-compliance.